Summary: Shanghai Longsheng Optronics New Materials Co., Ltd. (hereinafter referred to as "Longsheng Optronics") has recently completed a nearly 100 million yuan B+round of financing. This round of financing is jointly led by Yida Capital and Ancheng Capital, with multi-dimensional capital serving as the exclusive financial advisor. The funds are mainly used for production line construction, equipment procurement, personnel recruitment, and research and development investment.

Mr. Pan Xuan, General Manager of Longsheng Optronics, accepted an exclusive interview with well-known domestic media at 36 Carbon, elaborating in detail on the company's significant progress in technology research and development, intelligent manufacturing, product innovation, and market expansion. Let's review the content of this interview together.

Content Review

Longsheng Optronics is a high-tech enterprise that focuses on the research and development, manufacturing, and sales of new materials for liquid crystal dimming films. According to Pan Xuan, the general manager of the company, the core team of Longsheng Optronics has been engaged in the research and development of dimming film products since 2005, and has been deeply involved in the industry for nearly 20 years. The core material of the company is intelligent dimming film, and team members have participated in the compilation and review of national standards for dimming film glass. Over the years, they have accumulated profound technical strength, a large number of practical cases, and upstream and downstream industry chain resources.

On the entire vehicle, dimming film products have numerous application scenarios, such as sunroof, rear windshield, door glass, and triangular fixed windows. Especially with the solution of "panoramic sunroof+dimming film", the thermal insulation and temperature control effect of dimming film can be combined with the effect of sunroof glass releasing interior space and reducing body weight, creating a differentiated in car interior experience while further achieving the green goal of energy conservation and emission reduction.

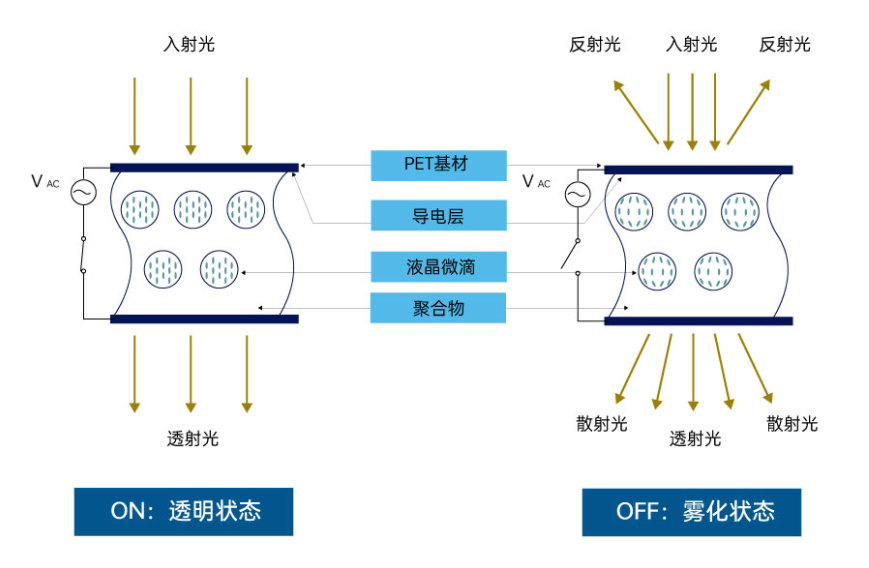

Dimming film materials mainly include different technical solutions such as PDLC (polymer dispersed liquid crystal), EC (electrochromic), SPD (suspended particle device), etc. Among them, PDLC is a flexible material. The principle is that the polymers in the liquid crystal film will be arranged in an orderly manner when powered on, and the glass will become transparent accordingly. When not powered on, the glass will present a transparent and opaque appearance.

Among the various technological routes mentioned above, PDLC dimming film currently has the highest maturity and cost-effectiveness (priced at 15-20% of SPD and 40-50% of EC), and is the mainstream solution recognized by downstream dimming glass manufacturers. General Manager Pan Xuan told 36 Carbon that Longsheng Optronics has been deeply involved in the PDLC route for more than 20 years. The company has independently developed liquid crystal formulas, PDLC wide temperature technology, advanced PDLC coating equipment, and automated production lines for subsequent processes. The various indicators of the dimming film products are at the forefront of the world and have passed vehicle level certification.

The product performance has passed the vehicle specification level certification, which is a major competitive advantage of Longsheng Optronics. It is reported that the vehicle certification standard first requires that the dimming film liquid crystal material must not undergo turning or translucency when subjected to bending and pressure, that is, it must not undergo "pressure induced discoloration". After solving this problem, Longsheng Optoelectronics has been conducting technical research for many years, achieving a product haze of over 95% at high temperatures of 95 ℃, and passing thermal aging tests at 105 ℃ for over 1000 hours, as well as light aging tests for 3000 hours in China and 5000 hours in Europe, as well as stable performance tests for power on and off under tens of thousands of hours of high temperature and high pressure conditions.

For automotive scenarios, Longsheng Optronics has mainly developed four product series: white wide temperature liquid crystal dimming film, black wide temperature liquid crystal dimming film, wide-angle liquid crystal dimming film, and dye liquid crystal dimming film. The products have multiple functions such as shading, privacy protection, thermal insulation, temperature and light control, and zoning.

The large-scale and efficient mass production capacity is a major highlight of Longsheng Optronics. It is worth mentioning that in November 2023, Longsheng Optronics won the Mass Production, New Materials, and Gold Award at the 8th China Automotive Parts Annual Contribution Award - Lingxuan Award.

The company's mass production capacity is mainly due to the self-developed front-end process core equipment and back-end process automation production lines. "In terms of front-end technology, in order to ensure the stability of high sensitivity and ultra-thin liquid crystal film products, spacer balls are usually used in the industry during coating." General Manager Pan Xuan told 36 Carbon, "However, spacer balls can also lead to reduced production efficiency, appearance wrinkles, white mist on the sides, and poor product performance, making it difficult to meet customers' needs for gradient effects and smooth appearance."

In contrast, Longsheng Optronics uses the proprietary coating equipment developed by itself, which can avoid the use of spacer balls during coating, while ensuring that PDLC film products achieve lower burst point, lower haze, and more anti-aging, without autoclave process, and the coating speed can reach more than five times that of the industry. At present, the company has two fully automatic coating equipment with an annual production capacity of over 1.8 million square meters.

In terms of downstream technology, Longsheng Optronics has taken the lead in achieving fully automated production, breaking the industry's traditional situation of relying solely on manual processing for important processes. It is reported that the PDLC film rear electrode side production equipment assembly line independently developed by Longsheng Optronics can not only improve the stability of the product electrode side, but also help achieve large-scale production and mass production of products. At present, the company has planned and constructed five or six automated production lines in the factory, with an annual production capacity of 1-2 million pieces.

Longsheng Optronics has established cooperative relationships with multiple first tier suppliers and well-known car companies, obtained order certification from domestic and foreign customers, and has strong commercialization capabilities. The company has reached cooperation with downstream automotive glass and sunroof giants such as Fuyao Glass, AGP, and Saint Gobain's global five glass factories, and has mass produced multiple mainstream automotive supply chains such as BMW, Audi, Volkswagen, and Lotus. The products have been imported into more than 40 designated vehicle models and 10 mass-produced vehicle models both domestically and internationally.

In response to customer needs, General Manager Pan Xuan introduced that the dimming field is currently mainly divided into two types of dimming methods: the conversion between transparent and opaque, and the conversion of contrast between light and dark in a transparent state. Regarding the conversion between transparency and opacity, Longsheng Optronics launched a wide-angle dimming film product in 2023, which can achieve consistent transparency at different angles on the front and side of the car, and ensure the lowest haze. On this basis, Longsheng Optoelectronics plans to launch a high contrast dimming film product with light to dark contrast conversion in 2024, and achieve large-scale mass production to meet the diversified needs of customers.

General Manager Pan Xuan also revealed that Longsheng Optronics will introduce a new coating production line in 2025 to further improve mass production capacity. In the future, the company will extend its application scenarios around PDLC dimming film technology and gradually enter the building curtain wall market.